This is an insight of each of the fibres we at the Simone Quinn label.

It’s our mission to make use of and return our products to Mother Nature with the same fibres She has provided for us, so She happily takes them back to biodegrade them.

Our Fibres……

The most beautiful fibre in the world to wear all year round. Wool is synonymous with quality, luxury and versatility. From clothing and footwear to using it for insulation, the wool fibre is also one of, if not the safest fibre in existence.

Merino Wool

100% Natural and Renewable: Wool is a natural protein fibre that is grown by domesticated sheep that produce a new fleece every year

100% biodegradable: When a wool product reaches its end-of life and is disposed of, the wool fibre readily decomposes in soil, slowly releasing valuable nutrients and carbon back into the earth, acting like a fertiliser. Wool does not contribute to microplastic pollution in our oceans or land.

Breathable and non-allergenic: An active fibre, Merino wool is thermoregulatory, keeping vou cool when it's hot and warm when it's cool.

Super Soft: Merino wool is finer than human hair. can be softer than cashmere and gentle on even the most sensitive skin.

Low Energy and Water Use: Wool uses 18% less energy than polyester and nearly 70% less water than cotton to produce 100 sweaters.

The Most Reused and Recycled Fibre: Wool is the most reused and recyclable apparel fibre and is valued for its many closed and open loop recycling applications. Although wool only makes up 1.2% of the virgin fibre supply, surveys have shown it represents about 5% of clothing donated to charity.

Harris Tweed Virgin Wool

The link below shows where our beautiful, 100% virgin wool from Scotland

is manually produced.

https://www.instagram.com/reel/DU-oB07DSmU/?igsh=aWY3bTd6cTZoaXdt

The Merino

Flax Linen

Harvesting: Flax is pulled up by the roots to get the longest possible fibres. The seed pods are removed and saved for planting or making linseed oil.

Fiber preparation: The harvested stalks are soaked in water or left in the field to allow bacteria to break down the outer layers, separating the inner fibres. The dried stalks are crushed to shatter the woody core. The broken stalks are scraped to remove any remaining woody material. The fibres are combed to align them, detangle them, and remove short, coarse fibres, leaving long, fine fibres for spinning.

Yarn and fabric creation: The long, prepared flax fibres are twisted together to create yarn. This can be done using wet spinning, where the fibres are kept damp for a smoother thread. The yarn is interlaced on a loom to create the final linen fabric.

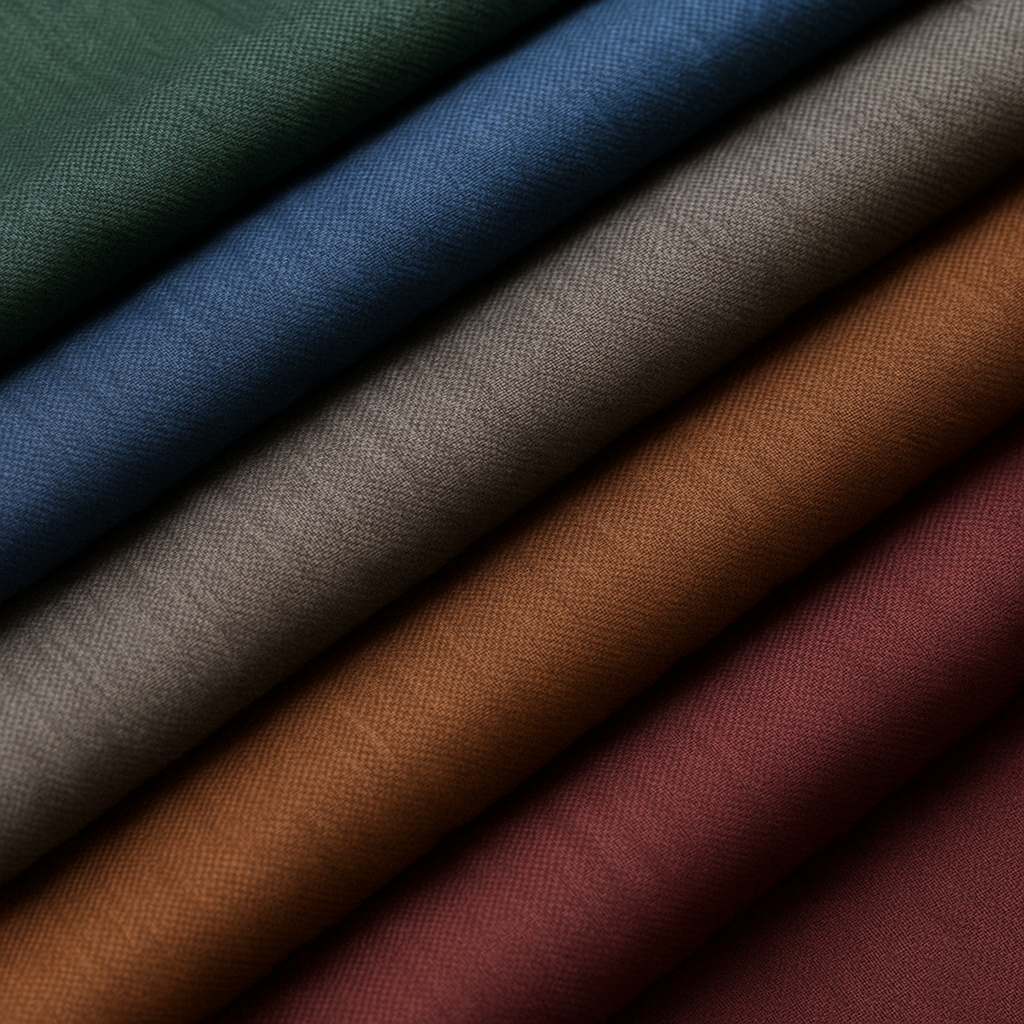

Finishing: The natural tan linen fabric can be bleached white. The white fabric can then be dyed any colour. Additional processes may be applied to make the fabric easier to care for or to achieve a desired texture, like stonewashing, where to fabric is placed into a washing machine, along with pumice stones to create the softer texture.

Flax linen is strong, durable, and breathable, which allows it to wick moisture and regulate temperature for coolness in summer and warmth in winter. It is also hypoallergenic, antibacterial, and biodegradable, making it a sustainable and healthy choice. The fabric becomes softer and more comfortable with each wash.

Flax Linen Harvesting

Flax Linen Fabric and Yarn

Organic Cotton

Farming - Grown without synthetic chemicals, relying on natural methods like composting.

Social Impact - Promotes fair prices for farmers and aims for better working conditions.

Product Quality - Harvested by hand, which can result in a purer, softer, and more durable fiber.

Hypoallergenic - Free from the residues of toxic chemicals, making it ideal for those with sensitive skin.

Organic Cotton Harvesting

Latex Rubber

Tapping: Workers make cuts in the bark of rubber trees to allow latex to flow out.

Collection: The latex is collected in cups and then gathered in large tanks.

Coagulation: An acid, such as eco formic acid, is added to the latex to cause it to thicken and solidify into a mass.

Rolling: The coagulated rubber is pressed through rollers to remove excess water and form thin sheets.

Drying and Smoking: The sheets are dried, often in smokehouses, to further reduce moisture and improve quality. This can result in a darker, smoked sheet or an air-dried sheet.

Baling: The final raw rubber sheets are then cut, folded into bales, and prepared for shipping.

Natural Latex Rubber Harvesting

Slide Tan Sole

Slide Black Sole

Cork

One of the most versatile materials in the world. Our footwear, which is designed and handcrafted by Simone herself, is predominantly made up of multiple internal layers of cork and for the upper layer of the sole, along with our natural latex rubber supportive internal cushions, creating shock absorption and giving our footwear a softer step.

Harvesting: The outer bark is manually removed from the cork oak tree. This process is sustainable and does not harm the tree, which can live for over 200 years.

Carbon Absorption: After harvesting, the tree absorbs three to five times more carbon dioxide as it regenerates its bark.

Minimal Waste: The manufacturing process is designed to be part of a circular economy, using almost all parts of the raw cork to create different products. For example, cork waste can be turned into new products like insulation boards or granules

Cork Harvesting

Cork Material

Cork Wedge Sole